How to Use Honda HDS Adjust Honda Valve Clearance

Chinaobd2 is a leading supplier of all kinds of Car Diagnostic Tool, Truck Diagnostic Tool, OBD2 Code Reader, Car Key Programmer,ECU Chip Tunning,etc. Currently, the top selling product including: VCDS VAG COM Cable, iProg+ Programmer, Scania VCI3

Need to adjust valve clearance for your Honda vehihles?We are a vehicle repair blogger which share this Honda valve clearance via Honda HDS here to help you to solve this problem.Let’s jump right in!

Preparation:

Honda HDS HIM Diagnostic Tool

Honda HDS Software Download

How to Install Honda HDS Software for DIY

Aftermarket Honda HDS Multiplatform Software Installation

Honda HDS Adjust Honda Valve Clearance Procedures:

NOTE: Connect the HDS to the DLC, and monitor ECT SENSOR 1. Adjust the valve clearance only when the engine coolant temperature is less than 100 °F (38 °C).

Remove the cylinder head cover

Set the No. 1 piston at top dead center (TDC). The punch mark (A) on the VTC actuator and the punch mark (B) on the exhaust camshaft sprocket should be at the top. Align the TDC marks (C) on the VTC actuator and the exhaust camshaft sprocket.

Select the correct feeler gauge for the valve clearance you are going to check.

Valve Clearance

Intake: 0.21-0.25 mm (0.009-0.009 in)

Exhaust: 0.25-0.29 mm (0.010-0.011 in)

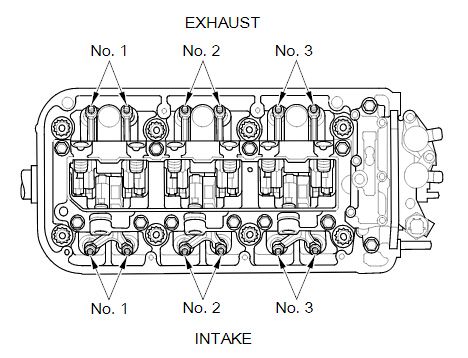

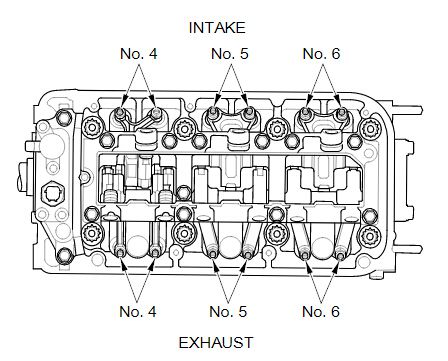

Rear

Front

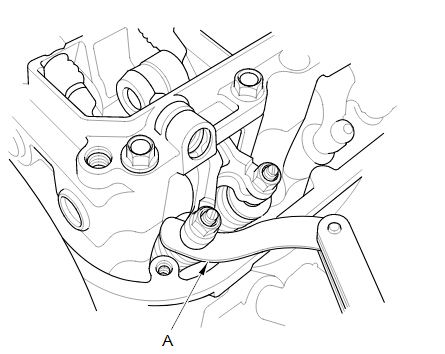

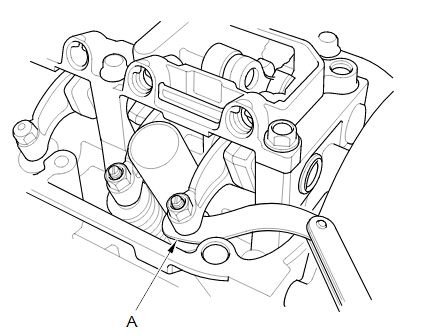

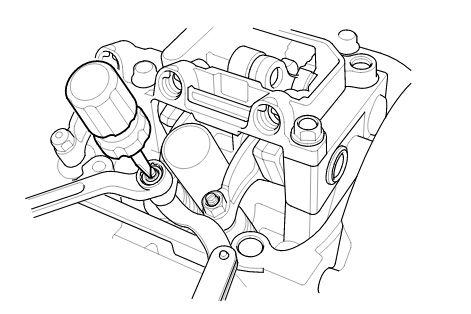

Insert the feeler gauge (A) between the adjusting screw (B) and the end of the valve stem on the No. 1 cylinder, and slide it back and forth; you should feel a slight amount of drag.

Intake

Exhaust

If you feel too much or too little drag, loosen the locknut with the locknut wrench and the adjuster, and turn the adjusting screw until the drag on the feeler gauge is correct.

Intake

Exhaust

Tighten the locknut to the specified torque, and recheck the clearance. Repeat the adjustment if necessary.

Specified Torque:

14 N·m (1.4 kgf·m, 10 lbf·ft)

Apply new engine oil to the nut threads.

Rotate the crankshaft clockwise. Align the pointer (A) on the front upper cover with the No. 4 piston TDC mark (B) on the front camshaft pulley.

Check and, if necessary, adjust the valve clearance on the No. 4 cylinder.

Rotate the crankshaft clockwise. Align the pointer (A) on the front upper cover with the No. 2 piston TDC mark (B) on the front camshaft pulley.

Check and, if necessary, adjust the valve clearance on the No. 2 cylinder..Rotate the crankshaft clockwise. Align the pointer (A) on the front upper cover with the No. 5 piston TDC mark (B) on the front camshaft pulley.

Check and, if necessary, adjust the valve clearance on the No. 5 cylinder.

Rotate the crankshaft clockwise. Align the pointer (A) on the front upper cover with the No. 3 piston TDC mark (B) on the front camshaft pulley.

Check and, if necessary, adjust the valve clearance on the No. 3 cylinder.

Rotate the crankshaft clockwise. Align the pointer (A) on the front upper cover with the No. 6 piston TDC mark (B) on the front camshaft pulley.

Check and, if necessary, adjust the valve clearance on the No. 6 cylinder.

Install the cylinder head covers.

This article tech Supported by China OBD2,

No comments:

Post a Comment