How to Tuning/Remap/Programming/Flashing Engine ECU

Chinaobd2 is a leading supplier of all kinds of Car Diagnostic Tool, Truck Diagnostic Tool, OBD2 Code Reader, Car Key Programmer,ECU Chip Tunning,etc. Currently, the top selling product including: VCDS VAG COM Cable, iProg+ Programmer, Scania VCI3

First a basic beginners guide introduction into world of car tuning and what you need to know:

The ECU of your car is like its brain. For your car to deliver it’s best performance you have to keep it in a fit condition at all times.

This is the only way to ensure that you get the best in both driving as well as handling. Modern day cars do not have manual controls. Nowadays sophisticated technology is being incorporated in the form of computerized controls that guide and ensure Engine performance.

Whenever you make a physical intervention the data pertaining to such intervention gets recorded in the memory banks of your car’s computer.

The computer uses the mapped data to work out the optimum control conditions in which the engine should function.

The ECU shuffles through the tons of data that come to it in the form of readings to decide the course of action that should be taken by the engine to ensure an ideal drive. The ECU tells your engine not only what to do but also how to do it. Thus the ECU in order to make accurate diagnosis on engine control utilizes stored data.

Even though you have made modifications in your car, the ECU still continues to get an input of the old data which is stored in it’s memory. This old data no longer is credible as it pertains to conditions that existed before the modification.

The input data to the ECU should pertain to the post modification situation of the components and parts introduced, while making the modification. This means that you have to erase the old data from memory and new data pertaining to post modification should be logged into the ECU memory by mapping in new readings. This is the reason why ECU resetting is essential for optimum performance after any modification has been carried out in your car.

The moment you have carried out the modification you should purge out existing data in your ECU’s memory. You should then feed in fresh data pertaining to the conditions that have come into existence post modification. The ECU has to operate on the newly acquired data as this new data reflects the true conditions post modification.

You should be well versed with the vital art of resetting the ECU of your car. You have to let your ECU adapt itself to the new situation arising out of the modification. Allow your ECU to relearn and perform.

Now therefore the step to be performed is to purge the old data and reset your ECU. Doing this allows it to adapt itself to new parts and efficiently perform post modification also. To reset the ECU you simply have to unplug the negative battery cable connection. Theoretically it is best to leave it in this disconnected condition for as long as you can. Practically leaving it disconnected overnight is more than enough.

After having left the cable disconnected for sufficient time you have to connect back the cable. Start the car and keep it running so that it warms up. This would not take more than 10 minutes at the most in summers. Once you have done this you have accomplished the ECU resetting. Shut off the engine.

You can now use your car whenever you feel like. ECU resetting is over.

You should remember a few points when doing the ECU setting. One important point that you should remember is not to reset ECU when using fuel additives or different octane fuel than you normally use. The idea is not to reset the ECU when using anything in your car that you normally don’t use. You should prepare the ECU to get adapted only to the conditions that it would normally encounter. This would also reduce the number of resets you will have to do to the ECU.

However if you are going to change the operating conditions on medium or long-term basis then you should reset your ECU. One such instance could be when you think of boosting octane.

Resetting the ECU when you choose to boost Octane becomes necessary because your ECU has a memory bank for octane.

This means that if you’ve been using lower octane, the response of ECU will correspond to lower octane with the booster matching lower octane performance.

The ECU response will continue to correspond to lower octane even though you have started using higher-octane fuel. This is because the ECU has not been reset for higher octane. Thus even though higher octane is in actual use, the data in ECU memory still corresponds to that of lower octane. This mismatch affects performance, as you are unable to derive the benefits of boosting the octane. Therefore you should reset your ECU periodically after filling up full tank in order to ensure that ECU adjustments for its octane memory are made afresh corresponding to the octane actually in use.

You can even customize resetting of your ECU so as to enable it to adapt itself to seasonal changes. Since humidity, air density, oxygen levels etc in air affect performance you could reset the ECU to adapt to these variables too.

The advantage of such resetting made to your ECU is that your car performs the best in every climatic condition. This lends versatility to your car- and all this at no cost.

Now let’s dive more into the technical detail of tuning – but still keeping it simple…

Back in the good old days, the task of timing the ignition spark was performed by the mechanical distributor.

The greater the RPM, the more the timing would advance. It was clunky and mechanical but seemed to work reasonably well.

This did a sufficiently good job, but for the most effective power you would need to vary the timing to a greater degree than a fixed ratio advance curve.

The electronic ignition system was born giving much finer control over fuel delivery and spark timing. You ended up with a perfect spark timing only in a limited RPM band.

A complete map of variables was entered into the ignition program and the preset timing would be read from a table.

Now air temperature, engine speed, engine load and even control over turbo/wastegate control & fuel delivery rates means that precise management of the engine ignition timing is possible and you can achieve the maximum power output throughout the rev range.

What does ECU remapping do?

Electronic ignition allows the manufacturer to fine tune economy at popular road speeds such as 30mph, 56mph and 70mph where most cars spend a large proportion of their time. (Some manufacturers in the 2016 cheat software scandal have even created code to detect test conditions and run super lean to pass emissions limits.)It is now possible to advance the timing if the throttle is wide open to give greater power or back off the timing when cruising at constant speed for improved economy.

Manufacturers do not want people breaking down, suffering premature parts failure or to get a reputation for uneconomical cars so they build in a wide margin of tolerance. Different countries use different grades of fuel and have varying degrees of extreme weather conditions, all these factors add to the fudge that has to be done to keep all the cars working well across the globe.

Each car that leaves the production line is also unique, some achieve 20bhp less and others can be 20bhp up on standard specs, depending on how well the components are machined and put together. So rather than put each car through a unique assessment and get a bespoke timing map, they adopt a standard one map fits all philosophy.

It is also a fact that manufacturers use the remap to produce different power versions of the same engine and get lower insurance cover ratings and better fuel consumption. You start to see the fantastic scope for improvement, when you add into the mix the fact that the average TorqueCars reader will be adding better performing components to the car, you have a really strong case for a remap.

Other things that the manufacturer builds in to their map equation is the possibility of user neglect i.e. infrequent servicing with items struggling like dirty plugs, bad leads, clogged air filter, partially blocked injectors etc… The list goes on.

” When a manufacturer creates a timing map they build into it a big margin of error to cope with: adverse temperature ranges, minor faults & bad conditions. In some countries emissions targets vary as measured by CO2, HC, NOx and these usually require a fudging of the one setup for all approach. “

Who should remap?

Anyone who has added performance parts to their engine should consider a remap. If your car is a turbo model & has electronically controlled fuel injection, there are massive power gains on offer and TorqueCars would strongly recommend a remap.What are the hidden costs or drawbacks? You will need to be prepared to keep the car serviced more frequently, and, sometimes decreasing the service interval by half. When you fill up you are also restricting yourself to high quality fuel and even high octane fuel if this was what the map was optimized for, and you must be prepared to replace components that fail due to the extra work they are doing.

When an engine is tuned to produce more power, you are also creating more stress and strain, so things will start to fail such as air flow sensors. Any weak spots in an engine usually show up a couple of months after a remap has been done. Generally the turbo/clutch weaknesses will manifest themselves clearly at this point. Also turbos can wear out, other major components like pistons and bearings will need care and attention and you will find that the clutch lasts a shorter time.

If you do not have a turbo there’s very little to be gained by a remap alone – perhaps only a few BHP so TorqueCars’ recommendation for non turbo cars is to modify everything else first (cams, pistons, increase compression, engine balance, air intake, exhaust, head work, bigger valves etc…) after these things have been done you can then consider a remap which will help you get the full benefit from them.

On the subject of turbos, (briefly though as we have a comprehensive article on turbos in the forced induction section), a remap will often introduce boost from lower down the rev range and because of this the turbo is running faster and hotter. In this situation you must let the turbo cool down a little before shutting off the engine, otherwise the oil will degrade and you will have an expensive turbo repair on your hands. Fitting a turbo timer will also help with this problem and keeps the engine ticking over.

Of course the amount of power you choose has a bearing on the reliability and cost of running the car. Many people go for an off the shelf remap which are on offer all over the country and typically cost around $260-$600.

This is better than the manufacturers map in that it uses tighter parameters but it is still a one size fits all job. If you are after big power gains and have changed major components like the turbo, waste gate and have done extensive engine work then a custom remap is the best option.

Switchable Remaps

Things have moved on and it is now possible to have a few maps stored which you can select from. It is typical to have a valet mode to stop the boy racers at the garage thrashing your pride and joy on the “test run” to bed in the new wiper blades they have fitted. Then there is often an economy option to give very frugal fuel consumption, particularly useful when cruising on long journeys.Then you have the ‘sport’ or ‘power’ modes which give lots of power and often require high octane fuel. TorqueCars strongly recommend that you get a switchable remap – it may cost a little more at the outset but you will avoid many of the pitfalls of running a high power remap all of the time by doing this and get the best of both worlds.

Some maps use the cruise control to choose a map, other companies offer handheld flash devices which allow you to choose a range of maps and upload these. It typically takes about 3 minutes to flash a car through the OBD port so is not an on the fly option.

Most people will run an economy map through the weekly commute and then go for a performance map at the weekend or a race map for track days.

Please do not confuse a remap with the little “tuning boxes” you can buy for $60 which generally contain little more than a $5 resistor and often do little more than fool the car into thinking the air is cooler than it is. If it was really this easy to get more power from a car then the manufacturers would have already done that themselves.

Some cars are not easy to remap, I remember that the Rover MEMS & Toyota ECU’s are a case in point. The Manufacturer holds the key to the ECU and locks their Map into their firmware. Some ECU’s are simply not reprogrammable. So what can you do? Is there an option? Well thankfully there is and they are called piggy back ECU’s or aftermarket ECU’s.

Piggy back & Aftermarket ECUs:

Piggy back ECUs connect between your existing ECU and the engine sensor inputs and outputs. All work slightly differently and apply some or all of the following combinations.Some will adjust the sensor readings such as air temp, engine speed, crank position and effectively lie to the standard ECU forcing a more aggressive timing. Some will actually perform their own calculations and take over control of some aspects of engine management like turbo waste gate control and ignition timing.

Some will take the standard ECU output and modify the signals sent to change timing and learn to guess the next output a split second before it is needed using the base ECU map and just enhancing it a little.

Tuning boxes are relatively new and these alter readings going to and from the ECU giving extra power or economy.

Aftermarket ECUs are often direct replacements for the car’s ECU and will take over all the functions associated with it. They are generally faster and able to cope with a wide variety of additional factors such as water/methanol injection and a turbo timer.

Be wary though, as some piggy back ECUs and aftermarket ECUs do not include knock protection. If this is the case then set your timing conservatively and use high octane fuel.

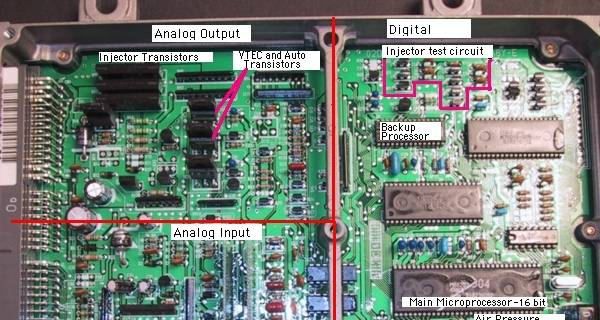

Part 1: ECU Back-to-Basics

Part 2: ECU HEX Coding

Part 1: ECU Back-to-Basics

3 Typical Questions When Attempting Car Tuning:

1.Should I get a “one size-fits all”?

2.Should I get off-the-shelf chips like (Mugen, Jet, Spoon, Skunk2, Comptech, Neuspeed, FF Squad, Inline4, Power XS, Bayou Performance). Or Dinan ECU – which are “best guess” chips?

3.Should I get one of those chips I see for sale on eBay all the time?

ANSWER 1:

First, don’t chip too early

There is no point in getting a new ECU program early in your engine build up and then later upgrading to bigger lift and duration cams, or larger injectors, bigger fuel pump, or an aftermarket IM/bigger bore TB , etc. , since these parts just render your “new” ECU program obsolete and useless (ie. any power gains from the chip are eliminated).

So please do not get your chip reprogrammed just after i/h/c/e , if you later plan on going for bigger & better things in the future. It’s supposed to be one of your last modifications and not one of your first, to prevent the need for multiple chip reprogrammings after each addition of a new modification.

The reason you see so many chips for resale on eBay?

Other enthusiasts made the mistake of buying a chip too early that was not programmed correctly for the unique way their engine package breathes. It made very little power for them , or likely made their engine run too rich, or both. They are now trying to recover the money lost from an obsolete or incompatible chip.

Then there are the programmers who take advantage of import enthusiasts who do not understand the performance difference between a pre-programmed, mail-order chip versus a chip tuned and programmed on your car at a dyno. They are selling them based on the attractiveness of convenience for unsuspecting people who don’t have a local programmer and dyno, the hyped hp gains from the magazine articles or ads, and a lower cost compared to other significant hp gain modifications, like cams or an intake manifold (IM).

ANSWER 2:

Second, What does an ECU do and what am I doing when I get a new chip ?

The ECU controls:

- the fuel map (ie. program commands for how much fuel to add at each rpm) and sequential firing of the injectors

- ignition map (program commands for how much spark timing to advance or retard from the baseline ignition timing you set at the distibutor cap at each rpm)

- VTEC switchover

- Redline

- Speed limiter (JDM and European models)

- Knock sensor warning

- Second O2 sensor CEL warning in OBD 2 and OBD 2b cars for testpipes and high flow cats and closed loop operations

- Activates the opening of the secondary runners’ valves based on the IAB vacuum input, if you have a dual stage IM (eg. 3rd gen. GSR)

When you get a new chip, the programmer has changed the program’s commands of the ignition map and fuel map in response to a change in air flow and rpm (ie. both are indicators of “engine load”). The amount of ignition timing and fuel delivery is changed for a given air flow and rpm compared to the stock program. The programmer can also remove or inactivate the sensor CEL warning codes and move the VTEC point, redline, and speed limiter points to anywhere you like.

What do these ECU program’s commands look like?

Example of a 3 dimensional ignition table of program commands (or “ignition map”):

Manifold Absolute Pressure or MAP which monitors air flow (Y axis), RPM (X-axis), and Ignition Advance/Retard from Baseline Timing (Z-axis).

There is also a 3-D fuel table (or “fuel map”) which has Intake Manifold Pressure (Y-axis), RPM (X-axis), and Fuel Values instead of spark Advance (Z-axis).

The program commands can be entered on 2 dimenional tables.

Example of a 2-Dimensional fuel table’s commands during a GSR’s VTEC cam lobe operation:

RPM down the Y axis to far left, MAP (mBar) across the top row, and fuel values for the injector duty cycle in the table cells.

Most (but not all) plug in chip replacements claim to be a ‘Mugen’ program. Typically these chips disable error reporting for most sensors and give about 40 % worse fuel economy. The chips are popular with engine swaps because they eliminate most error codes caused by poor wiring….The stock knock sensor is designed to compensate for different qualities of fuel, and has a limited scope of adjustment. It is not designed to co for detonation under boost and may be fooled by forged pistons rattling into retarding the ignition when knock is not present. Mugen recognizes this and does not have a knock sensor (input on their ECU).

ANSWER 3:

Third, “Best Guess” programs are not as good.

An “off the shelf” or mail order ECU is a programmer’s best guess at trying to make a program that will fit as many different engine combination of mods as possible…that’s why I call these “one-size-fits-all”. These usually get you in the no gain or 5% disappointment gain ballpark. You will not get major gains with these “best guess” chips. Save your money.

So you want to make major power gains (ie. 13-15% or at least 7 whp from midrange up) with an ECU reprogram?

Please get a true custom chip instead, programmed on YOUR unique car with its own combination of mods, on a dyno using a wideband exhaust O2 sensor/Air:Fuel Ratio meter. This is the only way to go, if you are serious about getting the most out of a computer program upgrade for a street/race setup. If you got your chip by mail then, please understand that you did not get the most out of it…even the custom pre-programmed, mail-order kind of chips. The only correct way is to do the reprogramming on the dyno. And this leads us to who do you go to?

If you are lucky like me and have a couple of local programmers with Honda experience near your town, then your local programmer will go with you to the dyno and work his experience in tuning on the laptop and EPROM or EEPROM burner.

If you do not have a local programmer or race shop that does programming, then I strongly recommend getting together with some friends and investing in a Hondata Stage 4 or P200 system. It allows YOU to tune YOUR car on the dyno or at the track using elapsed times between known rpm points.

It comes with a chip burner, chips ($25/each), emulation laptop capability, instructions, and tech support. Investing in a wide band O2 sensor like the MOTEC they sell is also a good idea. This takes the guess and disappointment out of ECU upgrading.

If you want to go at this alone, then an AEM EMS is worth looking into, since it has base programs and laptop emulation. This is a serious investment for serious people.

If neither of these appeal to you and you insist on getting a mail order chip knowing that it won’t be the best program, then stick to the known programmers (PM me if you want recommendations from people I’ve known who do a decent “best guess” chip). Most people who buy a mail order chip usually have a piggyback tuning box, like an Apex fuel controller (SAFC or VAFC) or Field SFC VTEC/fuel controller, and use those to further tune the fuel delivery on the dyno with a wideband O2 sensor.

Chip reprogramming at the dyno requires a wideband universal exhaust gas oxygen sensors (called an UEGO that you can get from dyno shop or race shop) to measure air:fuel ratio at each rpm. Expect at least 3-4 hr dyno time minimum to tune these even if you are experienced at partial and wide open throttle fuel tuning.

Other systems to consider are the Motec M4, Apex Power FC, Accel DFI, SDS EF3, and Electromotive Tec3. Compare processor speed (16 bit, 16 MHz versus 32 bit, 33MHz ), available baseline programs to get you going without startin from scratch, sensor compatibility, emulators availability, and a good track record for tech support/customer service (not just whether they have one or not).

- Why an ‘off the shelf’ mail order ECU will disappoint:

| …on most naturally aspirated engines operating on pump fuel, the only way to achieve tangible power gains is by increasing airflow through the engine. Chips cannot do this. Therefore they cannot make much difference in power output. Chip reprogrammers can richen the mixture slightly at full throttle and advance the ignition timing slightly perhaps but this would be at the expense of lowering the factory safety factors for detonation and emissions. The absolute maximum gain in this instance would be on the order of 5% and could be as little as 0%. Most independent tests that I have seen on performance chips for naturally aspirated engines have indeed shown minimal or no gains in acceleration. |

Chips for use in factory stock turbocharged applications can increase power substantially in some cases by raising the boost pressure. This again reduces the factory detonation limits and you risk engine damage. Without increasing fuel octane, you are asking for trouble especially if your engine does not have a knock sensor.

Finally, we have chip companies doing “custom” chips for modified engines. What does this involve? This is a technically sound modification only if your engine has the same mechanical mods as the motor on their dyno that the chip is being developed for. If your cams, heads, turbo, exhaust, intercooler, injectors, throttle body or fuel are different, the chip will not be correct for your engine. A chip made for an engine slightly different from yours will be slightly wrong under some conditions. In some cases, poor driveability and performance are the result.

SDS and Hondata agrees with me that the best way to rechip your computer is to program your ECU instead on the dyno on your car rather than buying a previously programmed “best guess” chip made to fit as many different engine packages as possible.

| The only way to get good results on a modified engine with different mods from the base engine is to take your vehicle to the tuners facility and get a true custom chip burnt for YOUR engine. This must be done on a chassis dyno then tested on the road also for driveabilty faults which often don’t show up on the dyno. This will cost more. |

| Before buying, do acceleration testing with a stopwatch, Vericom (or a GTech Pro) or at the strip. Have an objective measure of performance as your baseline before programming so that you have something unbiased and not subjective (like a butt dyno impression) to compare to afterwards. |

Follow all of the instructions provided by the chip maker when installing it.

Stick to reputable companies. Some people in the chip industry really don’t know what they are doing. Talk to some people first who have used a certain chip and see if they are satisfied.

Test your car to be sure that you got what you paid for. This is all good advice when buying any aftermarket devices such as ignition wires, ignition products, oil or fuel additives etc. which advertise a performance gain.

If it doesn’t do what it is advertised to do, you just got hosed and with some chips costing $300-500. This is something that you should not put up with.

Be careful. Some unscrupulous programmers will promise to sell you a “Mugen” like chip but in reality, all they have done is moved the redline higher and removed the CEL warnings. The advice to stick to known reputable programmers is wise, if you plan on mail orders.

What about standalone computers like a Hondata instead of a redone chip?

| If all of this doesn’t sound too good to you (in terms of chips), the alternative is a (standalone) programmable engine management system . These allow you to tune your engine yourself. This can be good and bad. The same things apply as above for the mail order chips. |

Understand that you will have to program all of the values to make the engine start, warm up, cruise, accelerate and run at full power. This can entail entering hundreds of points in most cases and you will require either a dyno or a long deserted road plus some indication of mixture strength to properly tune such a system. These systems are great for the knowledgeable person and a nightmare for the lay person.

Remember, both the chip that you buy or the chip in your (standalone) programmable ECU must have the proper values entered for your engine to run properly.

The main advantage of user programmable (standalone) systems is that they can be quickly changed, if a new mod is done or if not quite right whereas the factory type (mail order) chip must be changed or sent back to be redone, sometimes, several times at great cost.

If you are contemplating a strictly race situation, don’t bother with the factory ECU or chips at all. These were not designed for performance use and you will usually not get the kind of power required with factory hardware. This is when a programmable system is a must.

When considering buying a programmable system, here are a few tips:

Discuss your goals and needs with the tech people selling the system.

Make sure that the system will do what you require it to do. Don’t expect the impossible – you can’t expect a 400hp, 4 cylinder street car to have factory driveability, fuel economy, emission compliance, a smooth idle or long life on pump fuel. If you do, you are a nut and no one will talk to you. There is a reason why there are no factory cars like this driving around your neighborhood.

Removing the factory system and installing a stand alone system can be a lot of work. What hardware, skill and tools will you require to install the system? Can you handle it or do you know someone who can?

What factory options will you lose when removing the factory ECU?

If emission legality is a concern, find out if their system is legal and if it will likely pass in your area when properly programmed. Many systems are not legal for street use and many manufacturers will not guarantee emission compliance because they cannot control the programming.

Find out how easy the unit is to program and if you can handle it. If it is difficult to use, either don’t buy it or find a place where you can go to have it properly tuned.

Make sure that the company has good, accessible tech support, you may need it.

You are responsible, if you program the system too lean and melt your engine, don’t blame the system maker. If the engine runs like crap, you are probably asking the system to do something that it was not designed for or have not programmed it correctly. This is your problem now.

Read, understand and follow the manufacturers instructions. LISTEN. It will save you a lot of time. Remember, that the people who design and build this stuff likely know a hell of a lot more than you do about it.

If all of this discourages you, sell the present car and simply buy a faster one, you will probably be happier in the end.

- Some Basic ECU Info for OEM Honda ECUs

| Most ECUs up to 1996 hold their program information and data in small chips called ROMs. These are 28pin chips 1.5 inches by 0.6 inches. If we want to change either the program information (how the ECU behaves) or the data (usually the fuel and ignition tables), we need to replace the factory ROMs with our own. There are several different types of chip which can be used to replace the factory ROM. |

ROM:

ROMs are read only memory, which cannot be re-used once programmed(e.g. Atmel AT27C256 ROMs). ROMs are most suitable for the final tune for an engine, which is not going to be altered.

EPROM:

EPROMs are like ROMs except they have a quartz window which allows the EPROM to be erased and reused.Like ROMs, EPROMs are suitable for the final tune.

EEPROM:

EEPROMs can be electrically erased and re-programmed, usually much quicker than EPROMs (e.g. Atmel AT29C256). The advantage of EEPROM is that it is can be programmed in 20 seconds without erasing it first. EEPROMs are most suitable for use when tuning a car, but can be used as the final tune as well.

EPROM emulation:

An EPROM emulator is a device which emulates (acts like) an EPROM. It is a box of electronics which plugs into the ROM socket on the ECU, and a laptop or PC. The advantage of using an EPROM emulator is that the tuning information in the ECU can be changed quickly without unplugging or swapping ROMs.

There are two types of EPROM emulators: normal and real-time.

Normal EPROM emulators will shut the ECU down while the information in the ROM is updated.

Real-time EPROM emulators allow you to changetuning information while the engine is running.

All Honda ECUs have a part number which is located on the side of the ECU and inside the ECU on the connector. e.g. 37820-P72-A01

The part number consists of three components:

Honda’s part number for ECU, which is always 37820

Three characters (which are loosely related to the model of car/engine). e.g P72

Three characters (which are the revision of the ECU) e.g. A01

The middle three characters are the most useful to identify what the ECU is.

Different generation ECUs may use the same characters. e.g. a P72 OBD I ECU is different from a P72 OBD II ECU.

Here is a list of common ECUs (and the car model they come from):

PG6 : 88-89 Integra (all makes)

PM5 : 88-91 Civic/CRX DX

PM6 : 88-91 Civic/CRX SOHC Si

PM7 : 89-91 DOHC ZC (JDM ‘EF’ ECU)

PM8 : 88-91 CRX HF

PR2 : 89-91 ZC (Euro)

PR3 : 89-91 JDM B16A EF8/9

PR3 -J00 or J51 : 92 JDM Integra B16A EF8/9

PW0 : 89-91 JDM B16A EF8/9 DA6-XSi

PR4 : 90-91 Integra LS/GS

PS9 : 88-91 4 door Civic EX Auto

P05 : 92-95 OBD-1 Civic CX

P06 : 92-95 OBD-1 Civic DX

P07 : 92-95 OBD-1 Civic VX

P08 : 92-95 OBD-1 Civic D15 JDM

P0A : 94-95 OBD-1 Accord EX

P13 : 93-95 OBD-1 Prelude Vtec

P14 : 93-95 OBD-1 Prelude Si (non Vtec)

P27 : 92-95 OBD-1 EG JDM Civic 1600 sohc

P28 : 92-95 OBD-1 Civic Si/Ex

P30 : 92-95 OBD-1 DelSol DOHC Vtec Si/EG SiR

P54-G31 : 1997 Honda Accord 1.8 LS

P61 : 92-93 OBD-1 Integra GSR

P72 : 94-95 OBD-1 Integra GSR

P72 : 96-00 OBD-2 Integra GSR

P73 : 96-00 OBD-2 Integra Type-R (JDM & USDM)

P74/75: 92-95 OBD-1 Integra LS/GS

P75 : 96-00 OBD-2 Integra LS/GS

P2N : 96+ OBD-2 Civic HX Coupe

P2P : 96+ OBD-2 Civic EX Coupe

P2E : 96+ OBD-2 Civic DX Coupe

P2M : 96+ OBD-2 NZ Civic SOHC VTEC

P2T : 99+ OBD-? Civic Si Coupe

P5P : 97-00 OBD-2 Prelude Type-S (JDM ECU)

PBA : 97+ US Acura 1.6EL

PCT : 98+ JDM ITR / CTR

PCX : 99+ OBD-? S2000

ECU ROM Numbers: As further identification Honda ECUs have a software revision number inside the ECU. This is usually a two or three digit number stamped on the 28 pin ROM, or main processor. Accord and Prelude ECUs can use a letter and number code.

Injector Size Limit For Stock ECU:

What are the biggest injectors I can run with a stock ECU?

The ECU can be re-calibrated to suit any sized injector (make sure you match injector impedance if you are replacing you injectors). However, injectors take a finite amount of time to open and close, so the bigger injectors tend to be less accurate with their fueling at low durations, such as idle.

Much depends on the mechanics of the injector, and how quickly it can open and close. With disk type injectors (such as RC 440cc injectors) you cannot tell the difference between stock injectors and injectors which flow twice as much as stock injectors, once the ECU has been reprogrammed for the larger injectors (and there is no difference on the dyno either). With race engines we have run injectors up to 4 times the size of the stock injectors.

How come people say that the biggest injector I can run is 310 cc/min. ?

This assumes that you are not re-calibrating the ECU to the new injector size. If you don’t, the bigger injector will over-fuel. If this happens then the ECU will compensate to some degree using closed loopo peration to reduce the injector duration. The limit of the long term closed loop adjustment is about 40%, which is close to the increase in size from stock to 310cc injectors.

Disadvantages of Running High Fuel Pressure:

Some people, instead of buying a proper size injector to get more peak hp opt to push the limits of the current injector they have by cranking up the FP and running at near or over 80% duty cycle. Once you exceed a 20% increase from the maximum FP spec, you wear out the injectors faster and the ECU fuel map calibrations for the program are no longer applicable.

Other disadvantages of extra high FP:

· Fuel injectors require more current to open meaning they run hotter and are less reliable as a result.

· Fuel injectors can take longer to open.

· There is a greater tendency for the fuel to leak past the injector seals.

· There is a greater chance of rupturing the diaphram of the FPR (usually rated to 100 psi) dumping fuel into the intake.

So, you probably need to upgrade the injector and possibly the fuel pump (if you push FP or run high CR or boost) and if you exceed 310 cc/min then you will need an ECU re-program.

Part 2: ECU HEX Coding

This is a brief introduction on how to tune a sample car map file using a good ECU HEX editor like TOAD.

NOTE: This is only a very brief introduction to tuning. There are many forums online on how to edit map files.

STEP 1: Download the stock ECU load from the vehicle. This image is the raw data from the ECU memory and is the application and Operating System code for the ECU. It controls how the car runs. Above the code area you will find the Constants and Maps, among other things.

Take a look at the figure below…

In the hex dump window you see a series of highlighted bytes, 43 7A 00 00, and in the Inspector window you see “Float 250”.

This is showing a map or constant value, in 32 bit floating point format, of 250.

The next series of 4 bytes, 43 FA 00 00, is a value of 500.

A value of 00 00 00 00 is a zero value.

Notice there are lots of 32 bit floats in the area of memory. This is part of a table.

The 20 values shown are:

250, 500, 0,0, 9, 800, 1200, 1600, 2000, 2400, 2800, 3200, 3600, 4000, 4400, 4800, 5200, 5600, 6000 and 6400.

The values 200 and 500 are not RPM based on the magnitudes (RPM would not normally be lower than 650), the values 800 thru 6400 are most likely RPM values used in a lookup table or map.

What is a Map? Look at the array below…

The numbers in red represent RPM values, the green numbers represent Mass Air Flow and the numbers in the yellow matrix represent fuel injector pulse width.

The longer the injector pulse the more fuel gets injected into the rotor.

To find this table you would look for ascending RPM values, ascending MAP values and many fuel injector pulse values, RPM X MAP numbers, in this case 13X9. This is a purely hypothetical MAP for illustration only.

6

| RPM | ||||||||||||||

| MAF | 800 | 1200 | 1600 | 2000 | 2400 | 2800 | 3200 | 3600 | 4000 | 4400 | 4800 | 5200 | 5600 | |

| 100 | 90 | 19 | ||||||||||||

| 90 | 80 | 17 | ||||||||||||

| 80 | 70 | 15 | ||||||||||||

| 79 | 60 | 13 | ||||||||||||

| 68 | 50 | 11 | ||||||||||||

| 60 | 40 | 9 | ||||||||||||

| 52 | 30 | 6 | ||||||||||||

| 45 | 20 | 4 | ||||||||||||

| 40 | 10 | 3 |

To find a Constant, you need to know what to look for.

An RPM limit would be a 32bit float at 9000 for a standard transmission car or 7500 for a automatic.

You would do a search for “46 0C A0 00” to find all values of 9000.

Pick one and change to 8000 and see if you hit the RPM limit.

Not all values are stored as floats, there are also single byte values of 0-255, unknown if 16 bit integers are used.

Once you take a look at the MAP area in memory, you will see it’s nearly all floats or byte values.

This article tech Supported by China OBD2,

No comments:

Post a Comment