How to Replace Internal EGR Valve for Volvo L250H Wheel Loader

Chinaobd2 is a leading supplier of all kinds of Car Diagnostic Tool, Truck Diagnostic Tool, OBD2 Code Reader, Car Key Programmer,ECU Chip Tunning,etc. Currently, the top selling product including: VCDS VAG COM Cable, iProg+ Programmer, Scania VCI3

This is a instruction on how to replace internal EGR valve for Volvo L250H wheel loader.And you can find the more service & repair manual on Volvo PROSIS Parts and service software.

Internal EGR Valve Removing:

1.Place the machine in service position 1, see Service position.

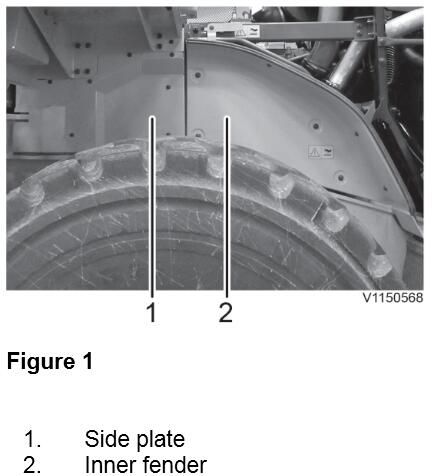

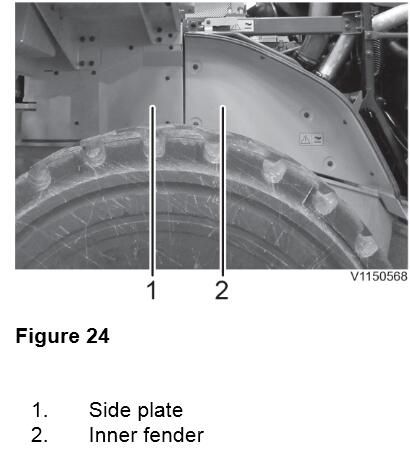

2.Remove the inner fender and side plate on the machine’s left side.

3.Remove the flex pipe, see Exhaust pipe flexible tube, replacing.

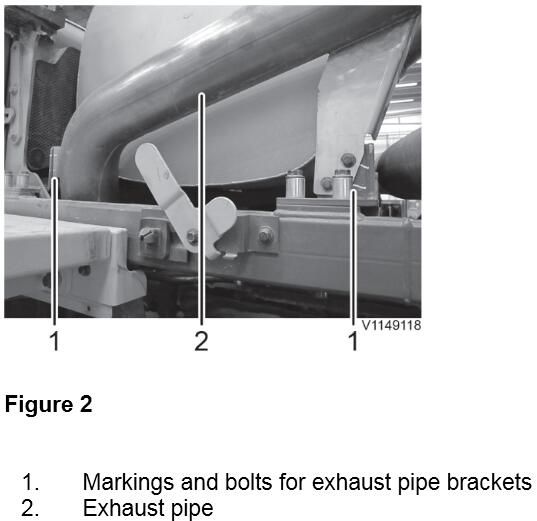

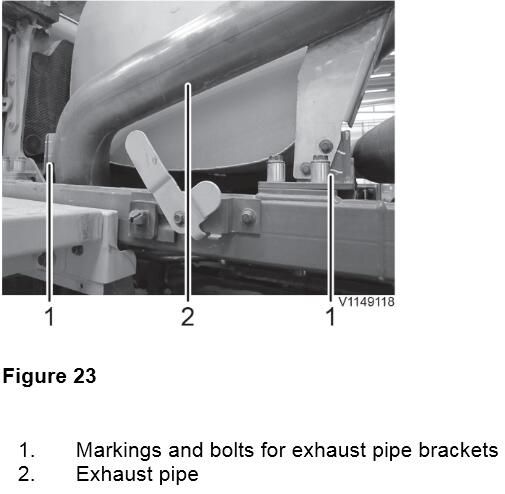

4.Mark the brackets for the exhaust pipe to make reinstallation easier. Remove the V-clamp and the bolts from the bracket for the exhaust pipe (4 pcs.). Remove the exhaust pipe.

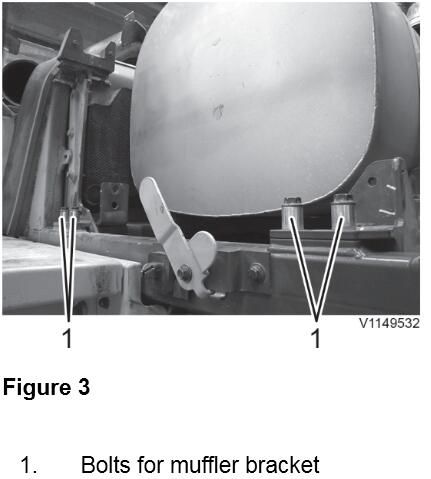

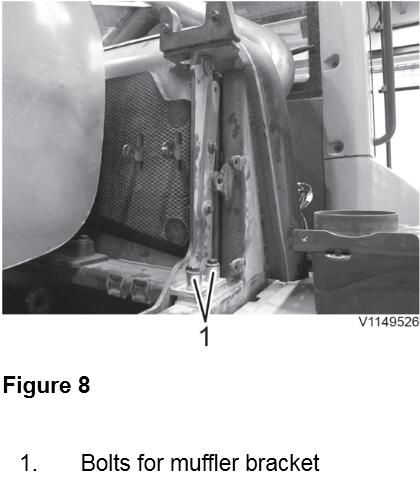

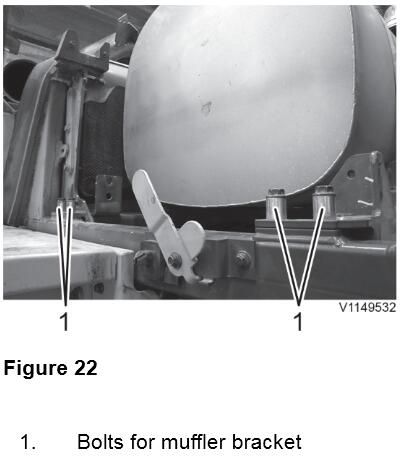

5.Remove the bolts from the muffler bracket (4 pcs.) on the machine’s left side.

6.Remove the inner fender on the machine’s right side.

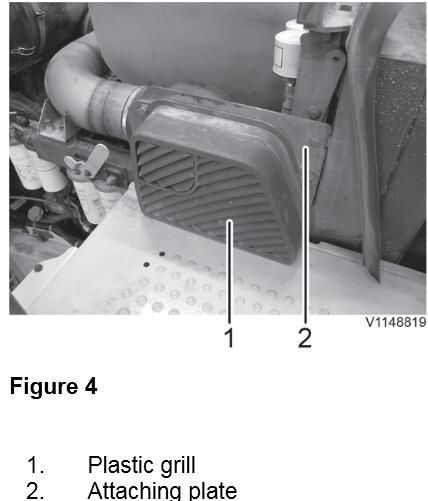

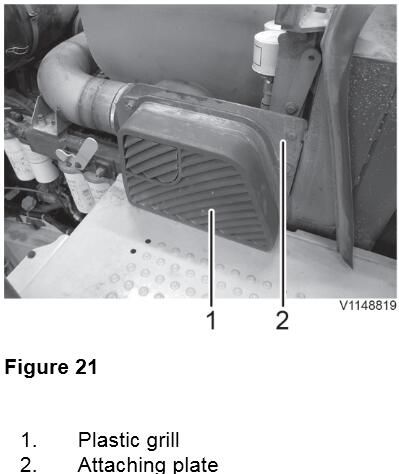

7.Remove the plastic grill and the air inlet’s attaching plate.

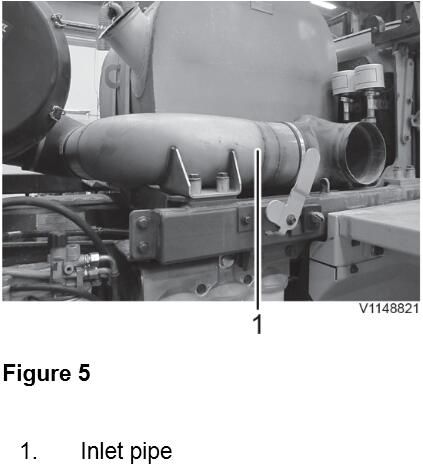

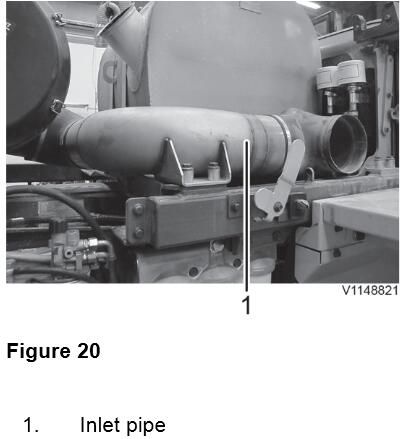

8.Remove the inlet pipe.

9.Remove the air cleaner.

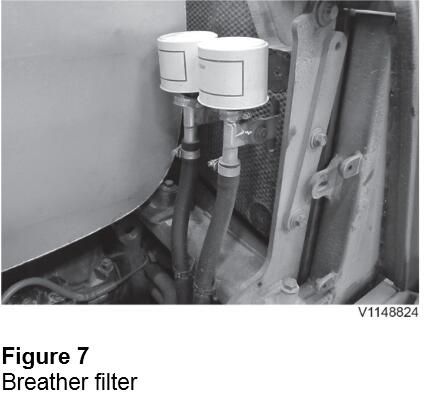

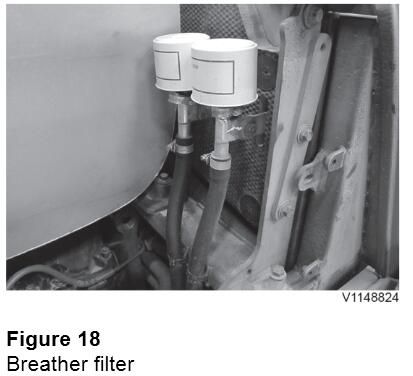

10.Remove the breather filters.

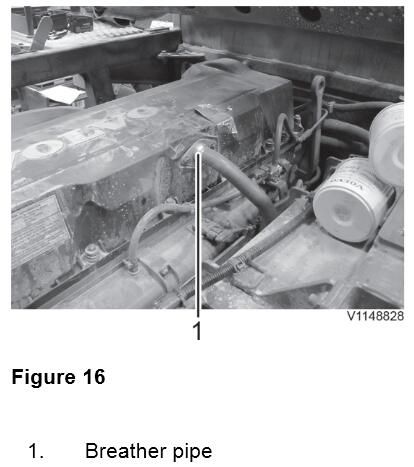

11.Remove the bolts from the muffler bracket on the machine’s right side.

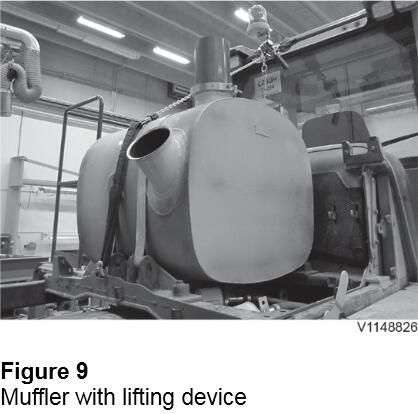

12.Install a shackle M8 in the bracket’s lifting point and connect a sling 0.5 m to it. Install the ratchet block in the sling and the roof bar.

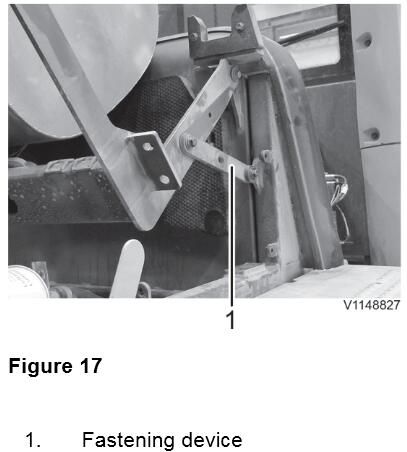

13.Lean the muffler and secure it on both sides with the pre-assembled fastening device.

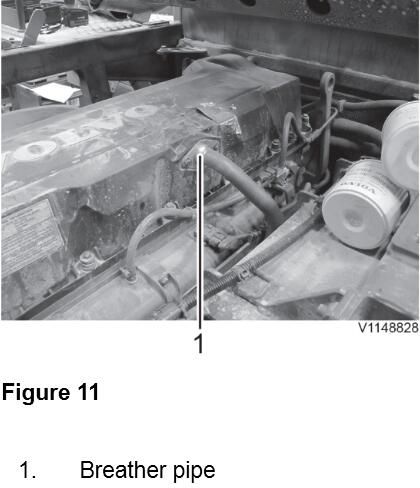

14.Loosen the clamps from the breather pipe and disconnect it from the valve cover. Cut off the cable ties for the hoses.

15.Remove the valve cover.

NOTE!

Be careful not to damage the hose nipple for the pierburg valve.

16.Remove the sealing strip from the valve cover.

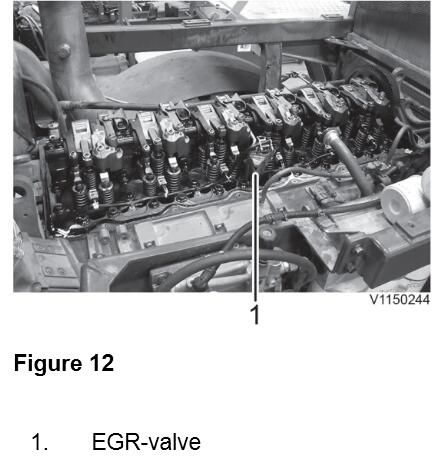

17.Unplug the connector for the EGR-valve and remove the EGR-valve.

Internal EGR Valve Installing:

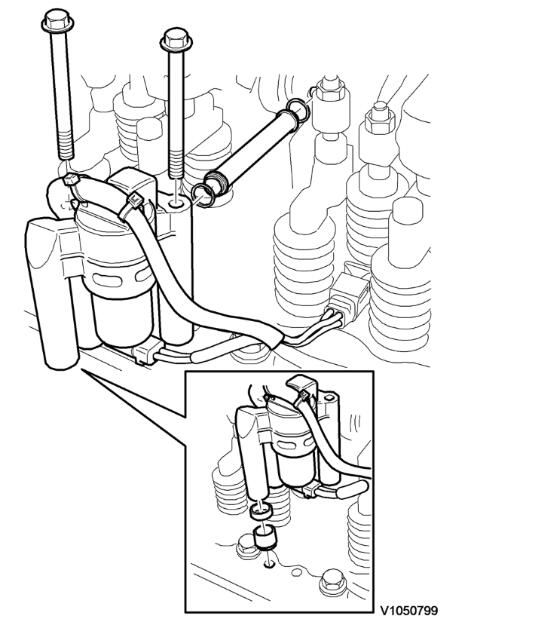

18.Oil in new seal rings and install them on the oil pipe. Push in the end in the rocker arm shaft. Install the new EGR-valve together with the spacer between the valve and the cylinder head. Check that the spacer and seals end up in correct position before tightening the bolts.

19.Install a new sealing strip in the valve cover.

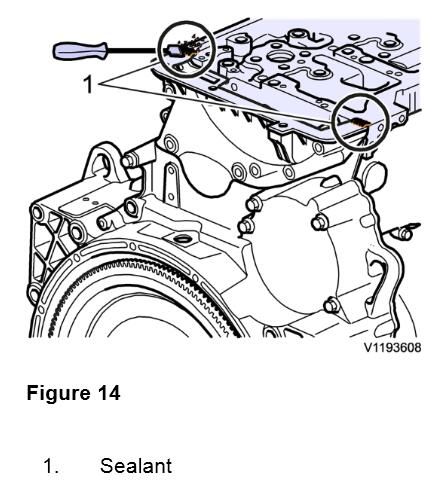

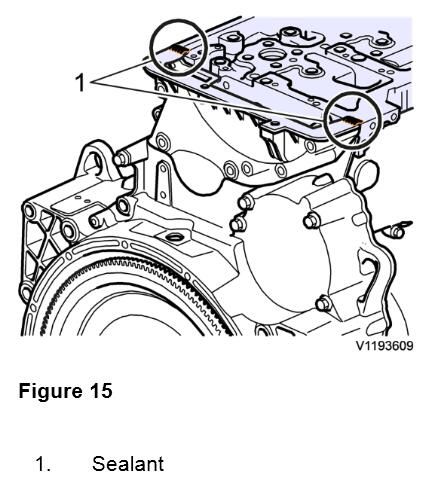

20.Remove the old sealant from the contact surfaces.

21.Apply two strings of sealant, approx. Ø 2 mm (0.08 in), according to the image.

22.Install the valve cover and tighten the bolts.

23.Connect the breather pipe to the valve cover. Install new cable ties for the hoses.

24.Loosen the fastening device and restore the muffler to its original position. Remove the lifting device.

25.Install the bolts for the muffler bracket by hand on both sides.

26.Install the breather filters.

27.Install the air cleaner by hand.

NOTE!

Remember the hose clamps for pipes and hoses.

28.Tighten the front bolts for the muffler bracket on the right side.

29.Install the inlet pipe with the rear bolts for the muffler bracket on the right side.

30.Tighten the air cleaner and the hose clamps.

31.Install the air inlet’s attaching plate and the plastic grill by hand. Tighten all bolts and clamps.

32.Tighten the bolts for the muffler bracket on the left side.

33.Install a new gasket and V-clamp on the exhaust pipe. Install the exhaust pipe by hand and adjust according to markings.

34.Install the flex pipe

35.Tighten all bolts and clamps for the exhaust pipe.

36.Install the side plate and the inner fenders.

37.Restore the machine.

This article tech Supported by China OBD2,